SET : 1

1. Write the differential equations of the following liquid level process as shown in figure

(click on the image to have a clear view)

Derive the transfer function H(S)/M(S) of this liquid level process.

What is the order of this system?

2. Give an example for interacting first order elements in series.

Write the differential equation for this combination and determine the transfer function.

Comment on the transfer function.

3. Explain with a neat sketch depecting the error vs controller output, the principle of a proportional controller action.

With an example explain how offset error in proportional controller occurs. Suggest a way to overcome offset error.

4. Briefly explain the principle of operation of a “displacement type” pneumatic P.D controller. How the “derivative time” can be adjusted in this controller.

Outline the design steps involved in developing an electronic PI controller.

5. What is meant by process tuning and list the various methods of tuning of PID parameters.

Discuss process reaction method for control loop tuning.

6. Explain the essential features of a control valve.

Explain the different responses of the 3 main types of control valves with respect to stem position and give reasoning.

7. A heating furnace requires a control valve passing 10gpm preheated light fuel oil (sp.gr = 0.8) at full load and only 2gpm at the smallest heating load. The source pressure constant at 50psig, but there is 10psig drop in the oil preheater and 20psig drop at the furnace burner nozzles. Remaining pressure drop occurs only at control valve when it is fully opened.

a) Find out control valve size required for the above application

b) Find out required rangeability of the valve.

c) Find out character coefficient.

8. Draw the feed forward and feed back control systems that regulate the flow through the pipe? Discuss about both the control systems and give reasons to select any of the two systems in maintaining the desired flow.

SET : 2

The above single capacitance level process has a normal operating head of 1.2 meter and a normal value of outflow of 3375 cubiccentimeter per seconds. The cross section area of the vessel is 0.54 sqmt. If the resistance to the flow is parabolic, determine the time constant of the system.

Show that the time constant of the above process is proportional to the time required to change the fluid in the vessel.

- Say whether heated tank and an immersed thermometer with negligible interaction is interacting or non – interacting. Justify your answer.

Write the differential equations and determine the transfer functions individually for heated tank and thermometer.

Determine the overall transfer function of this combination. How is this transfer function related with the individual transfer function.

- Explain with analytical expression, the concept of a single controller mode which is anticipatory in nature.

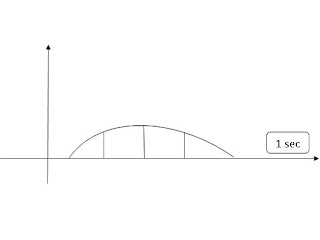

Why a pure derivative is not preffered? Draw the derivative controller output for the error given below figure (assume the relevant settings)

- What are the advantages of the force type pneumatic controllers. Describe with neat diagrams, the working of a force type pneumatic proportional controller.

Explain the working principle of a hydraulic proportional controller. How proportional gain can be adjusted in this controller.

- Repeated

- Give the principle of the control valve and give its o/p equation.

A pressure difference of 1.5 psi occur across a constriction in a 4cm diameter pipe. The constriction constant is 0.008wm/s(kpa)1/2. Find 1) the flowrate in m3/sec 2) flow velocity in m/s.

- Repeat

- Write short notes on

a) Material balance in a distillation column.

b) Quality control (top & bottom) distillation column.

c) Quantity control (top & distillation) distillation column.

SET : 3

- Write the different equations for the following liquid level process & hence derive the transfer function of the system as shown in figure

Say whether the above system is interacting or non – interacting. Justify your answer.

What are the effective time constants for this liquid level process?

- Repeat

- Repeat

- Explain in detail, the realization of proportional – integral action with aid of bellows, flapper – nozzle etc.

Draw a 3 mode electronic controller and derive the expression for the output voltage.

- Explain the following terms as applicable to system evaluation with necessary graphs

a) Stability

b) Measure of quality

Discuss the quarter – amplitude criterion to evaluate the response.

- Explain the principle of hydraulic actuator.

Explain a hydraulic servo system.

- Write short notes on :

a) Globe valves

b) Ball valves

c) Louvers

- Explain the nature of multivariable system.

Explain notation & interaction used in multivariable system.

SET : 4

1 – 7 REPEAT

8.Explain the closed loop characterization of cascade control systems.